Single Drop Products

Capacity

Category

Overall Length

Overall Width

Overall Front Height

Fording Depth

Gooseneck Length

5th Wheel Height

Upper Deck Height

Rear Deck Height

Load Well Length

King Pin Setting

Swing Clearance

Main Beam Center

Axle Spacing

Number of Axle

Axle Track

Beaver Tail Length

RAMPS

Cross Member

Main Frame

Side Rail

Neck

Axle Capacity

King Pin

Tires

Wheels

Brakes

ABS

Landing Gear

Suspension

Lighting

Connector

Decking

Outriggers

D Rings

Tie Downs

Winches & Webbings

Container Locks

Front Header

Stake Pocket

Finish

Plates/Markings

00443946

Parameters of Product

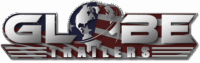

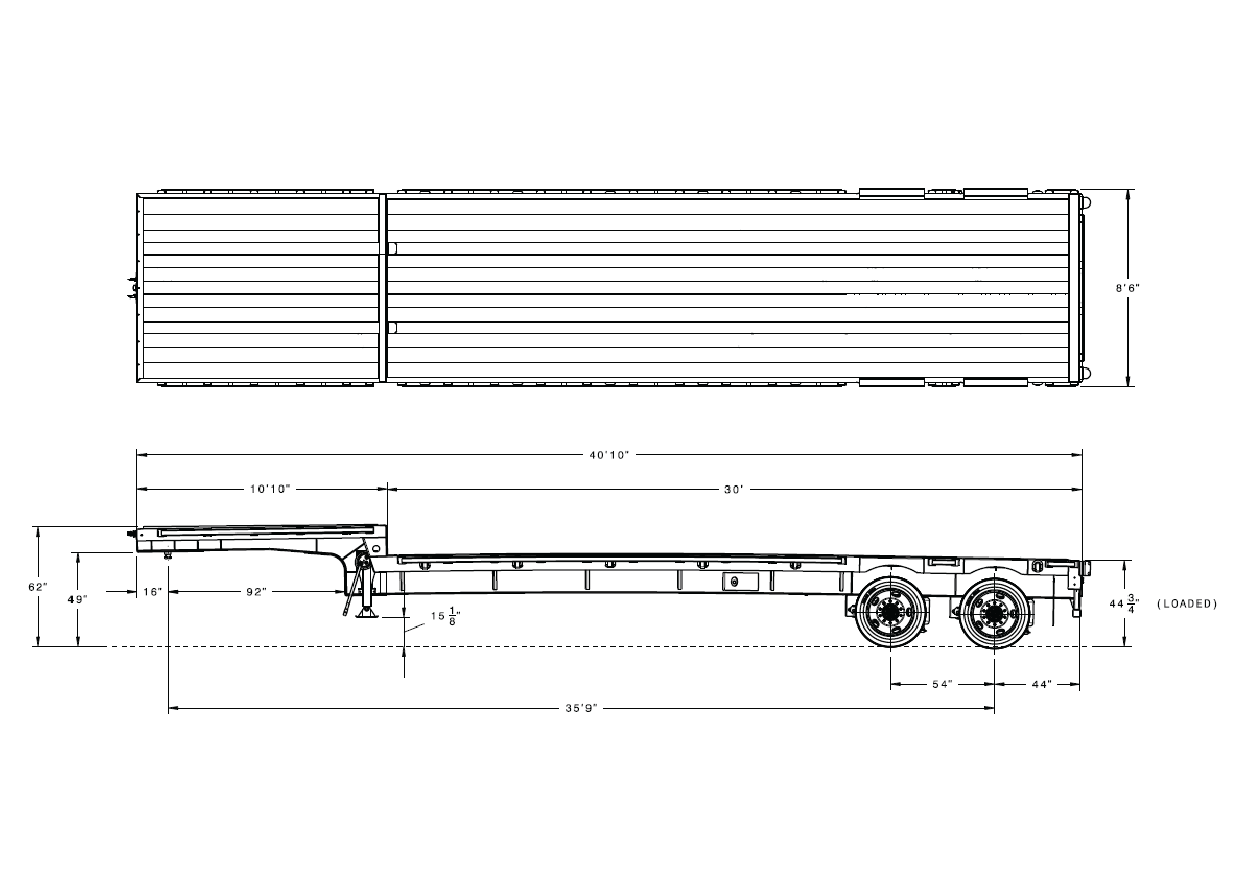

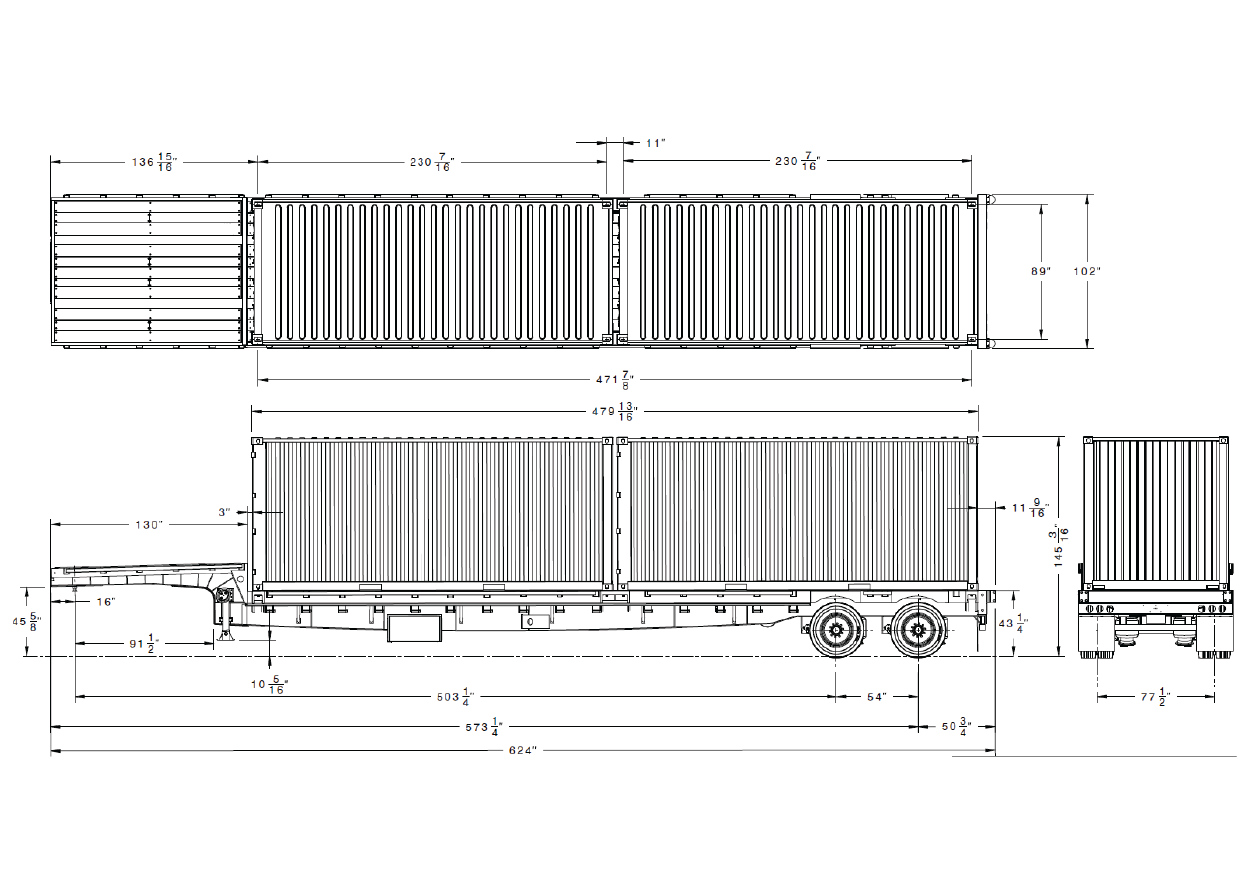

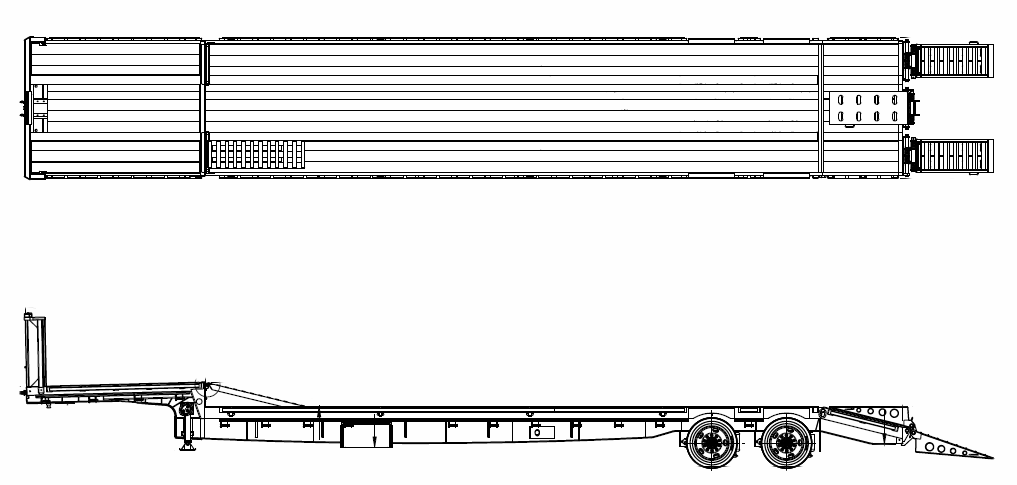

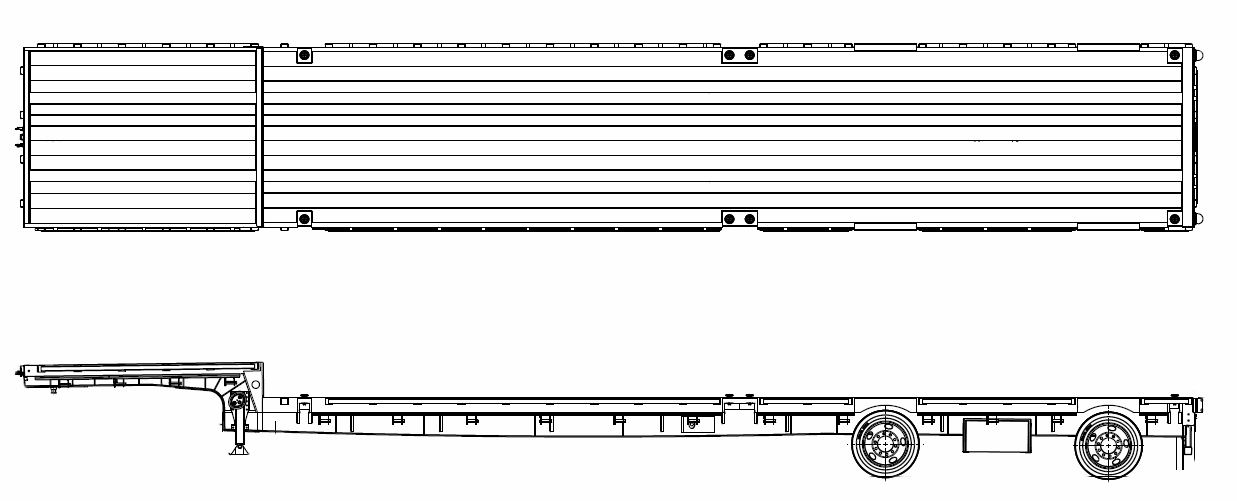

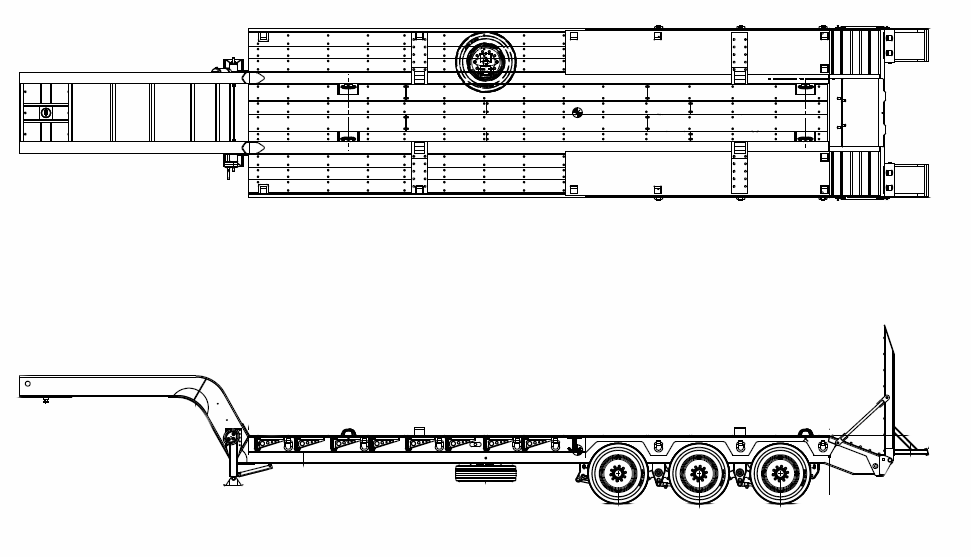

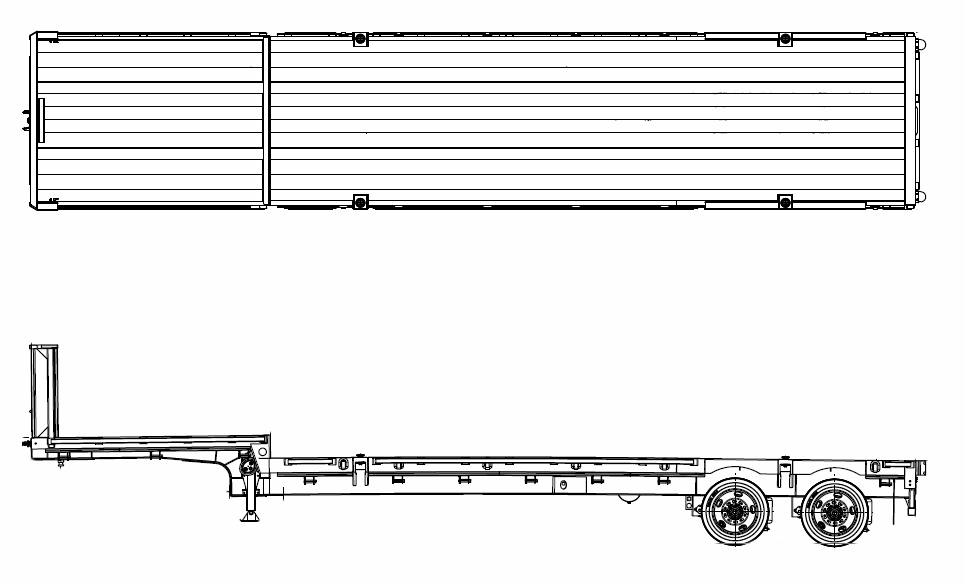

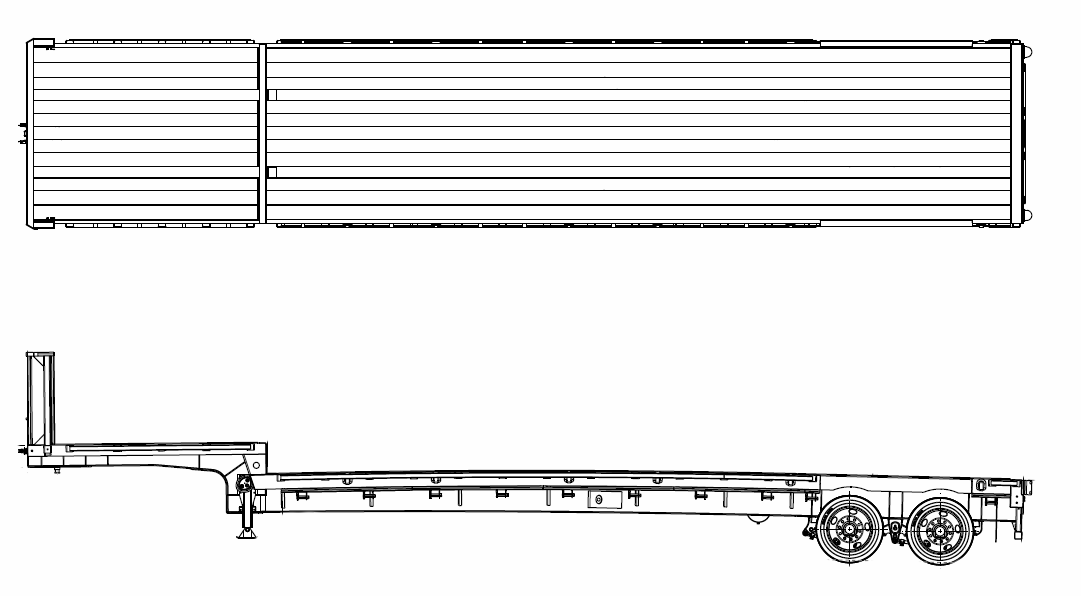

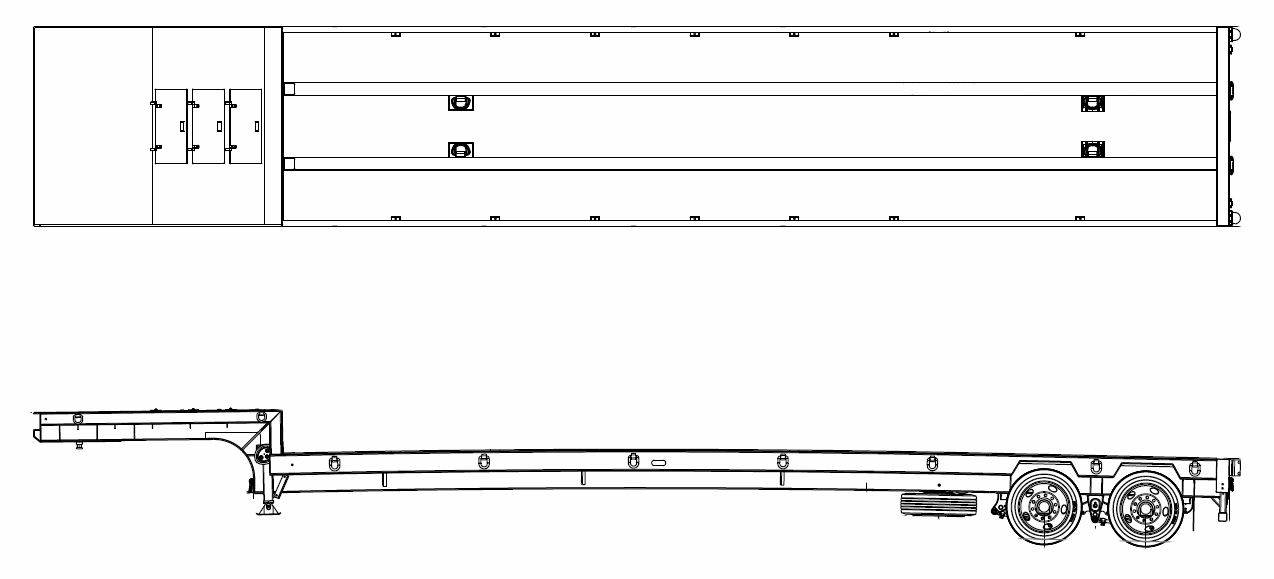

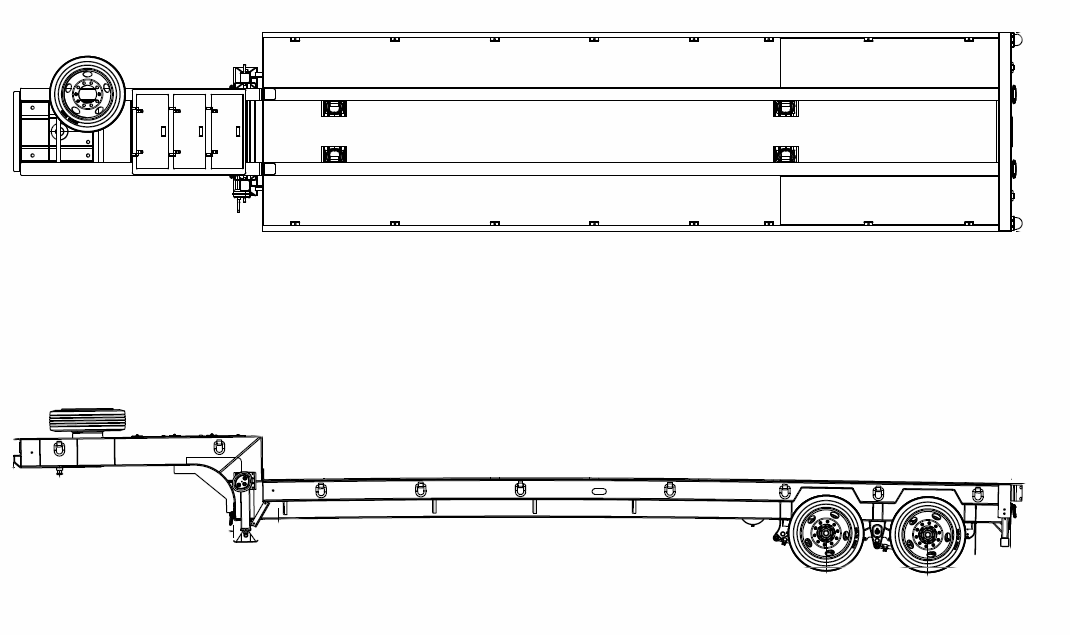

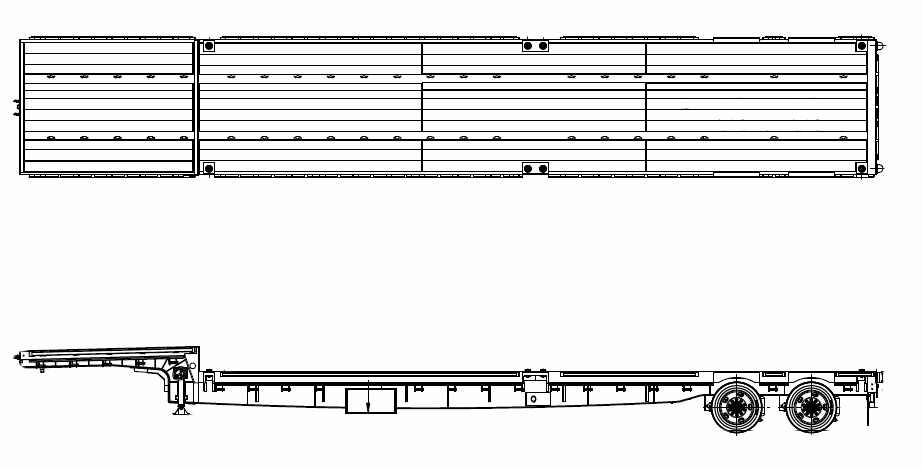

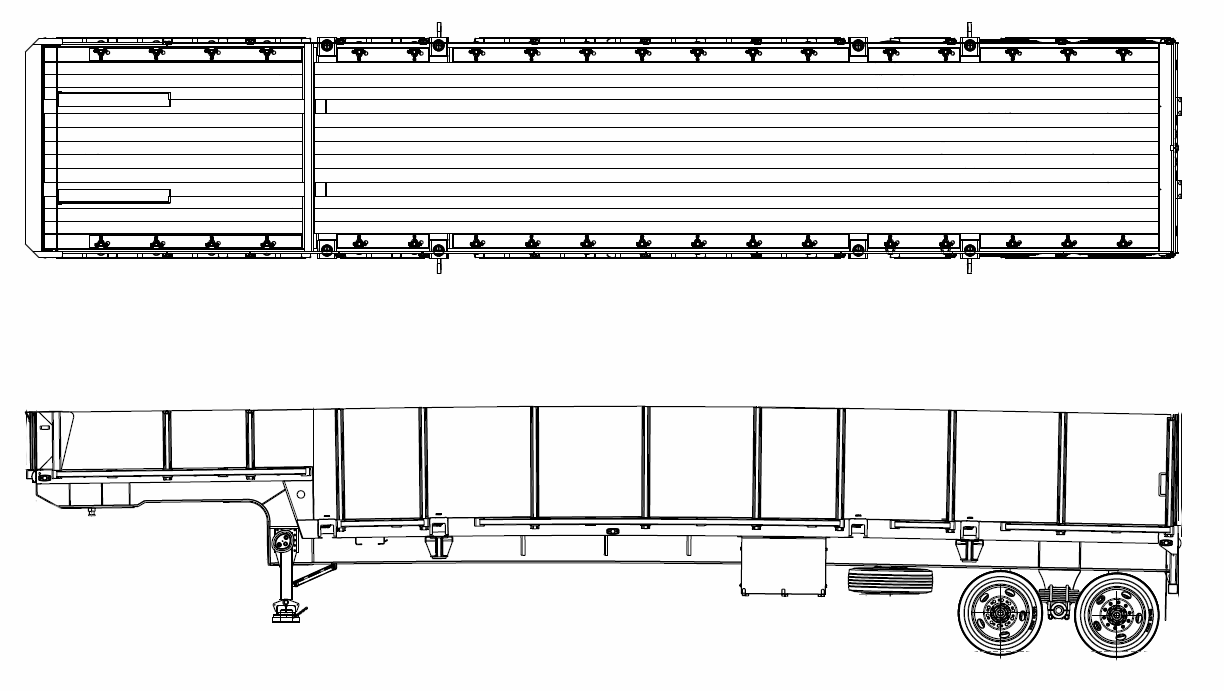

Single Drop Trailer

Model Number

GTFS22.52-43

Capacity

22.5 Ton

Category

Special

Overall Length

510-inch, 552-inch

Overall Width

96-inch

Overall Front Height

103

Fording Depth

30

Gooseneck Length

120-inch

5th Wheel Height

62-inch

Upper Deck Height

79

Rear Deck Height

52.5

Load Well Length

375-inch

King Pin Setting

24

Swing Clearance

85-inch

Main Beam Center

42.0625

Axle Spacing

50

Number of Axle

2 ea

Axle Track

71.5

Beaver Tail Length

NA

RAMPS

NA

Cross Member

4-inch Jr. I-Beams on 24-inch Centers

Main Frame

Fabricated I-Beam

Side Rail

6-inch Structural Channel

Neck

Full Width(Wood Covered)

Axle Capacity

25K

King Pin

2-inch Heavy Duty

Tires

255/70R X 22.5 H

Wheels

8.25 x 22.5, 10 hole hub piloted steel disc wheels

Brakes

16 ½-inch X 7 Full Air Brakes

ABS

4S2M

Landing Gear

2-Speed landing gear with fabricated flip-up foot

Suspension

Heavy duty single point

Lighting

Lighting LED in Rubber Grommet

Connector

7 Way SAE Connector

Decking

Apitong Flooring

Outriggers

No

D Rings

Yes

Tie Downs

Yes

Winches & Webbings

No

Container Locks

Eight (8) ISO container locks located on deck, accommodating one (1) 20' ISO in two (2) different locations

Front Header

25-inch Front header provided 10-inch wrap around, side rack panel kit provided, tarp kit provided with bows & securing/fastening items (ropes & straps)

Stake Pocket

24-inch on center, protected on all three sides of the platform by rub rail 2-inch x 3/8-inch thick

Finish

Sandblasted to Near White Zinc Primed and Powder Coated Desert Tan

Plates/Markings

NA

Notes

1. Lockable toolbox 24" x 24" x 36" installed for storage of with padlocks and keys (all keyed alike).

2. Manifest box

3. Hubodometer - front axle driver side

4. BII (Basic Issue Items)

a. Two (2) ground boards

b. Two (2) rubber chock blocks

c. Lug wrench, socket, and torsion bar and pipe.

d. One (1) 20-Ton hydraulic jack

e. Two-piece, 48" galvanized breaker bar for tire wrench.

3. Black mud flaps located behind rear axles.

4. Reflectors are amber on each of the front corners and each side with red on each rear corner.

5. Trailer conforms to MIL-STD-1366, MIL-STD-810, & MIL-11DBK-1791 for (Transportability, Rail Transport, Marine Transport, Highway Transport, Air Transport Includes C141, C5, C117 Aircrafts).

6. Trailer is be equipped with Tie-Down & Sling provisions in accordance with MIL-STD-209 & MIL-STD-1366, all provisions are labeled accordingly.

7. Trailer conforms to MIL-STD-130 with identification plates showing specific U1D markings. Plate includes all relevent tata specified in the purchase description. Plates conform to A-A-50271.

8. Trailer is equipped with instruction plates and diagrams describing procedures followed for operation, service, & lubrications. Plates are in accordance with A-A-50271 & affixed to the trailer using screws, bolts, or rivets.

9. Trailer has a shipping plate with a silhouette showing the transport configuration, weight, center of gravity, as well as location & capacity of the slinging & tie-down provisions.

10. Weld procedures & qualifications are in accordance with D1.1.

11. Trailer design incorporates MIL-STD-1472 sections 5.9 & 5.9.18 for both males & females.

12. Operation, Maintenance Manual, Service Manual (Parts & Service Sections)

2. Manifest box

3. Hubodometer - front axle driver side

4. BII (Basic Issue Items)

a. Two (2) ground boards

b. Two (2) rubber chock blocks

c. Lug wrench, socket, and torsion bar and pipe.

d. One (1) 20-Ton hydraulic jack

e. Two-piece, 48" galvanized breaker bar for tire wrench.

3. Black mud flaps located behind rear axles.

4. Reflectors are amber on each of the front corners and each side with red on each rear corner.

5. Trailer conforms to MIL-STD-1366, MIL-STD-810, & MIL-11DBK-1791 for (Transportability, Rail Transport, Marine Transport, Highway Transport, Air Transport Includes C141, C5, C117 Aircrafts).

6. Trailer is be equipped with Tie-Down & Sling provisions in accordance with MIL-STD-209 & MIL-STD-1366, all provisions are labeled accordingly.

7. Trailer conforms to MIL-STD-130 with identification plates showing specific U1D markings. Plate includes all relevent tata specified in the purchase description. Plates conform to A-A-50271.

8. Trailer is equipped with instruction plates and diagrams describing procedures followed for operation, service, & lubrications. Plates are in accordance with A-A-50271 & affixed to the trailer using screws, bolts, or rivets.

9. Trailer has a shipping plate with a silhouette showing the transport configuration, weight, center of gravity, as well as location & capacity of the slinging & tie-down provisions.

10. Weld procedures & qualifications are in accordance with D1.1.

11. Trailer design incorporates MIL-STD-1472 sections 5.9 & 5.9.18 for both males & females.

12. Operation, Maintenance Manual, Service Manual (Parts & Service Sections)